SAE Grade 5 vs. Grade 8: A Breakthrough Comprehensive Guide

Identifiers

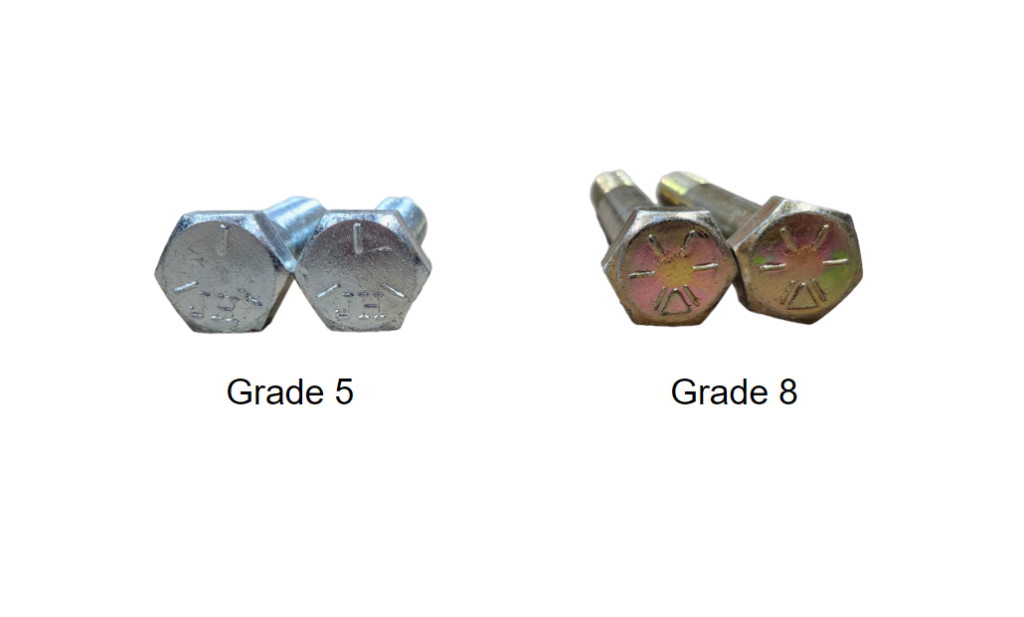

Before we delve into the differences between SAE grade 5 vs. grade 8, we need to learn how to identify the grade of a fastener using its head markings. Hex cap screws, carriage bolts, plow bolts, and hex bolts, to name a few, will have two main identifiers on its head: the manufacture’s insignia and ‘radial lines’. Looking at the picture, the grade 5 hex cap screws have a stamped “JH”. This is an example of a manufacturer’s insignia and a common one you will see. Another common insignia in North America, seen on the grade 8’s, is a triangle. It makes no difference as to who produces the fasteners as they are all created to the same specifications outlined by the Society of Automotive Engineers (SAE J429 Materials & Chemical Properties).

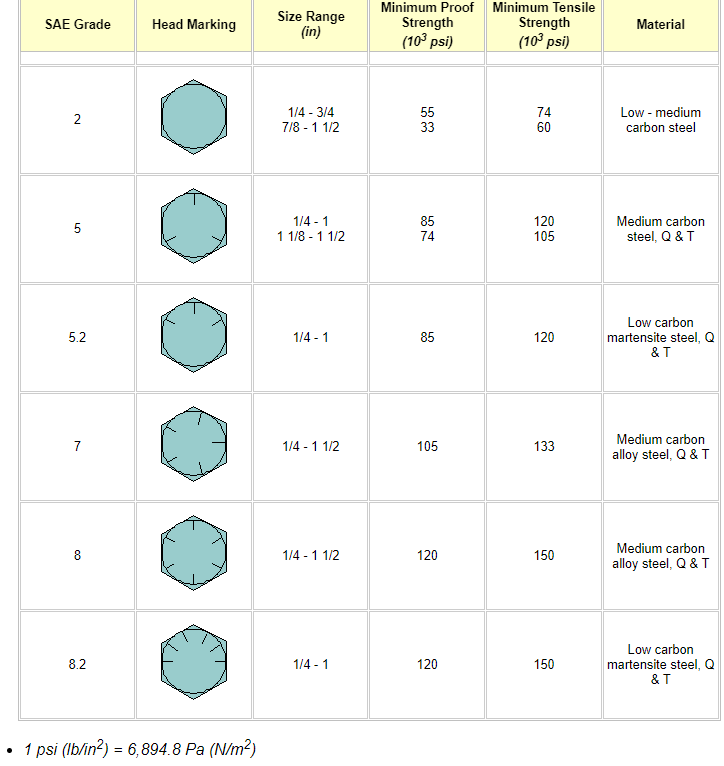

Unlike the manufacturer’s mark, the radial lines or tick marks are standardized per SAE and will thus be the same across all bolts. A general rule of thumb is to take the amount of radial lines on the head and add 2 to arrive at the correct SAE grade. For example, grade 5 bolts have 3 lines (3 + 2 gets you 5), grade 8 have 6 (6 + 2 = 8), and grade 2 have no radial lines (0 + 2 = 2). Like with most things in the fastener world though, there are plenty of exceptions to these rules. One notable exception is “L9” or grade 9 bolts, a Brighton Best International trademark that features 9 lines breaking away from the SAE +2 identification system.

Differences?

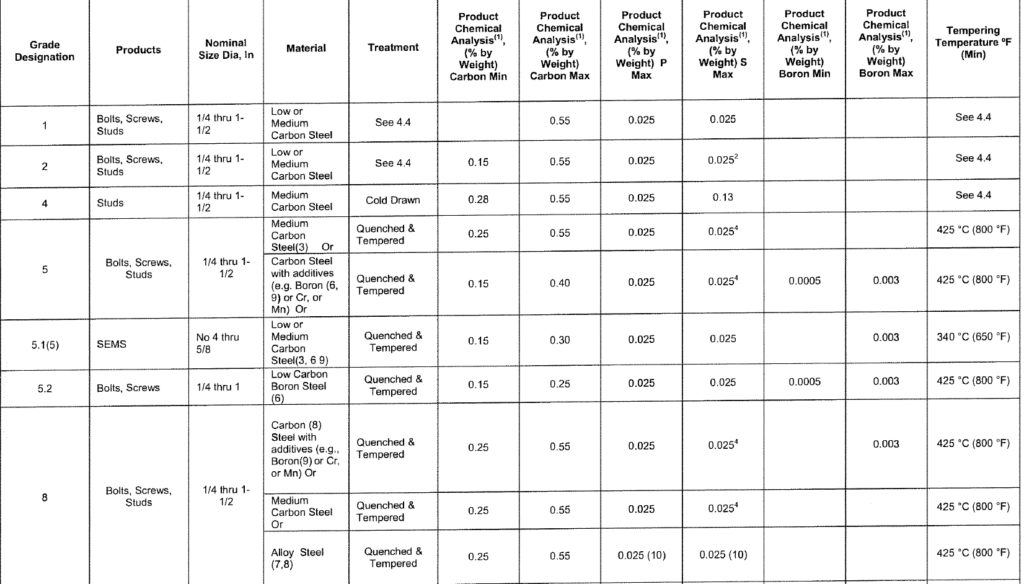

Now that we have established how to correctly identify SAE grade 5 and grade 8 bolts, we can move onto their differences. Simply put, the biggest difference in making grade 8 fasteners vs. grade 5 is how the parts are heat treated. Grade 5 is medium carbon steel that has been quenched & tempered and then heat treated to a Rockwell hardness of C25-C34 or C19-C30 depending on the nominal size. Grade 5 parts are tempered for longer, resulting in a softer bolt. Grade 8 is medium carbon alloy steel that has also been quenched & tempered but heat-treated to a Rockwell hardness of C33-C39. “Alloy steel” in this context refers to steel that has boron, chromium, and magnesium added to strengthen it. Surprising to many, grade 5 and grade 8 steel have the same carbon min – max as a % by weight of 0.25-0.55%. In most cases they have identical phosphorous and sulfur maxes of 0.025%. Therefore, as you can see below in the excerpt from SAE J429 there is overlap in the allowable materials for grade 5 and grade 8 fasteners. There’s even a note below this chart that says medium carbon alloy steel can be used for grade 5 parts at the manufacturers discretion. This would not be common practice though due to the higher cost and strength associated with alloy steel (manufacturers must sell it as grade 5 at grade 5 prices then).

But before we get too mired down in the J429 specifications. We need to understand and focus on the practicality for you. The higher hardness of grade 8 alloy steel means it has a higher minimum proof strength of 120,000 PSI and tensile strength 150,000 PSI. Grade 5’s proof strength range is between 74,000 and 85,000 PSI while the tensile strength is 105,000-120,000 PSI. As a side note, the minimum grade 9 tensile strength is 180,000 PSI.

Applications and Myths

Grade 8 fasteners are better suited for situations in which high strength is required as they are generally stronger. Automotive: Grade 8 is commonly used to secure engine components and other parts that are subjected to high forces and loads. Used to mate pieces of heavy equipment or machinery. Aerospace: Secure aircraft components for the same reason they are used in the automotive industry. Recycling: Tub and horizontal grinders require grade 8 hex cap screws to fasten their grinding tips and wear plates to better resist the high forces of the machine’s RPM and loads incurred from tree debris. Although grade 8 fasteners are stronger, their manufacturing process increases hydrogen embrittlement, making them more brittle than grade 5. The higher brittleness of grade 8 means over torquing a grade 8 hex cap screw can gall the threads more easily than a grade 5 bolt leading to an earlier failure. I.e., grade 5 is generally more forgiving if improperly torqued because it is more malleable. The brittleness of grade 8 fasteners also means they run a higher risk of shearing/snapping when approaching their resistance threshold whereas grade 5 will first physically deform before completely breaking.

Ultimately, there is a great amount of cross-over in applicability of grade 5 and grade 8 fasteners. For example, depending on the snow plow manufacturer, they will either fasten their blades using grade 5 plow bolts or grade 8 ones. The grade 8 plow bolts will almost always have more longevity, as they better handle the higher and continued resistance forces associated with running into an uneven asphalt surface. However, if a grade 8 is improperly torqued, it is possible that a grade 5 plow bolt could outlast its grade 8 counterpart in rare instances, highlighting the need for proper installation. As stated previously, due to the brittle nature of grade 8 hardware, a grade 8 plow bolt is more likely to snap off a plow blade once it has a reached its resistance threshold causing the instrument to detach whereas a grade 5 plow bolt will first physically deform before breaking. Both instances require replacement. However, the resistance force that causes a grade 5 plow bolt to snap or deform will most likely only leave micro fissures in a grade 8 plow bolt but still leave it in a usable state (micro fissures and stretching over time will decrease the maximum strength of hardware and thus increase its likelihood of failure). In this snow plow example, the choice between grade 5 and grade 8 plow bolts somewhat comes down to user preference. Spend less money upfront but potentially replace the parts more often? Or, spend more money upfront and replace them less often. Of course, if you are selling the plows to an end user, that customer may appreciate the extra longevity of not having to send their plows in to get serviced as often which could boost your reputation for having quality products. This idea extending beyond just snow plows.

In summary, grade 8 is “stronger” but that strength and associated brittleness could become a double edged sword in certain applications such as improper torquing. Sometimes you have installations that do not require such high strength and can therefore save yourself money purchasing grade 5 products or even weaker grades. As an electrician, do you really need to fasten an electrical box to a static, unmoving wall with grade 8 parts? Probably not. Grade 2 might be a suitable and cheaper alternative.

*Reminder: always consult with the OEM’s manual and provided specifications first before making any purchasing decisions. You are responsible if you decide to try hardware not recommended by the manufacturer.

Need to know which “grade” nut, washer, nylon insert lock, all metal lock nut, split lock washer, etc. should go with a grade 8 bolt or grade 5 part?